|

Since the turn of the millennium, scanning technology has gone from an exotic application to a realistic option for recording archaeological sites and objects. Though the hardware and software remain relatively expensive, use of the technology through rental or use agreements has put it within the reach of many archaeological projects. As scanning technology has matured, archaeology has become a viable area of competition for technology manufacturers. This was evident in the vendor display area of the Computer Applications in Archaeology (CAA) 2007 conference in Berlin. The displays were dominated by scanning companies offering hardware, software and services. Each manufacturer demonstrated the niche area of its scanning tool: environment, building, interior, or object. Displays featured large data sets from large-scale scanners to on-site demonstration of scanners designed to record smaller objects and artifacts.

For those who have looked into the purchase of an object scanner in the last six months, one manufacturer was noticeably missing, NextEngine, of SantaMonica, California, currently the maker of the best-selling scanner. Released in August, 2006, the NextEngine Desktop 3D Scanner was announced at SIGGRAPH, the premier computer science graphics conference. The release targeted computer graphics scientists and industrial designers; with a price of $2495 (discounted price for educational institutions) and performance specifications that match scanners sold at ten times the cost, it has caught the attention of other professions.

|

|

Fig. 1 - The NextEngine scanner and turntable (left) and with object, gripper, and computer (right).

The Desktop 3D Scanner is shipped in a tough briefcase-sized box with a carrying handle. It efficiently packs the cereal box-sized scanner (9" x 4" x 11", 7lbs.), the motorized turntable, the part gripper and software. The assembly instructions are simple, accessible and easily followed; in less than an hour the equipment can be unpacked, the software installed and the first test item scanned.

The aluminum-cased scanner contains two arrays of four solid state lasers, two 3.0 megapixel cameras, and two lights for image capture. The arrayed lasers and sensors use NextEngine MultiStripe Laser Technology and synchronous RGB color texture capture to produce digital models with textured surfaces. The scanner is complemented by a rotary servo positioner which is auto-incremented under software control. Separate power is required for the scanner, which is connected to the computer and turntable with USB 2.0 cables.

Objects are held in front of the scanner by the positioning plate which can accommodate objects weighing up to twenty pounds and measuring up to 8 inches in diameter and 11 inches in height. Larger objects can be scanned in part, composite captured, and assembled in the scan alignment software.

The ScanStudio software provided has three purposes: to focus and define the scan parameters, to align multiple scans, and to post-process aligned scan data. The software interface has been designed to support the typical scan project workflow from left to right across controls located at the top of the screen. Individual scans appear as thumbnails across the bottom. The first controls available invoke the camera, scan density and intensity controls.

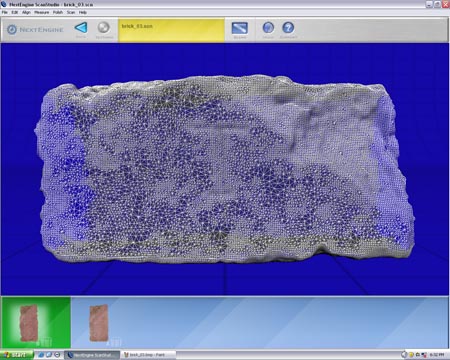

Optimal scanning of an object requires some experimentation. The software and hardware support experimentation with short scan times, readily available scan results and scan controls that are easy to read and manipulate. Multiple views of the object also provide feedback on scan density and color. The scanned object can be seen with textured surface, surface, mesh and scan points (see figures to the right).

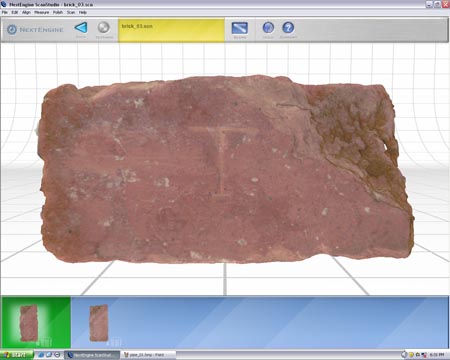

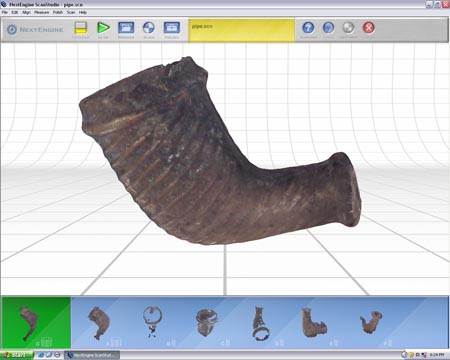

As part of the review process a number of items from the excavations at Montpelier, Virginia, were scanned. They range in size and are of varied material: a brick with an incised letter, a clay pipe with delicate ridges and a number of antique nails. Though the scanning was generally very successful, through the process a number of common scanning issues concerning dark surfaces and digital model size emerged.

|  |

|  |

Fig. 2 - The brick from Montpelier in a photograph (upper left), and in screen shots as textured surface, surface, and scanned points (upper right, lower left, and lower right respectively).

The variations in the surface of brick, seen in figure 2, were easily and accurately recorded by the scanner. The incised letter is visible in the geometry and the photographic data, with the general surface color variations recorded, but slightly washed out by the bright photo lights in the scanner case. The dulling of the surface in the digital model was evident in all the test scans. Another concern is the ultimate file size. Recording objects with indiscriminate density can become a problem for older, underpowered computers. An eye to data-point economy is advisable when scanning and processing.

The clay pipe scan successfully detected and recorded the fine ridges and texture details. The black and dark areas presented a challenge and took multiple scans from various angles to fully record the surface. NextEngine provides a powder to temporarily coat dark, highly polished or transparent objects or areas. This may not be a suitable solution with objects for which contamination is an issue. The entire clay pipe model needed 10 scans to complete the exterior and oversample dark areas. Seven scans were taken on the rotary mount and were automatically composited, with three scans hand-positioned to patch the obscured ends and dark areas.

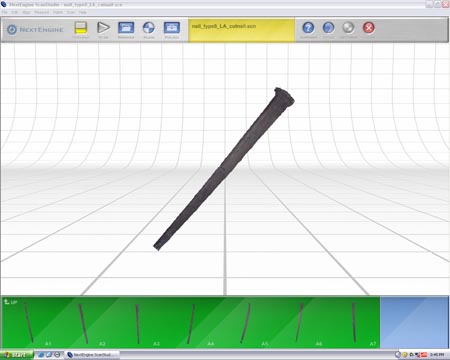

Eight nail types, varying in size from one and a half inches to two and a half inches were scanned using the macro setting at high density. The resulting scans were automatically combined and aligned providing detailed surfaces on which tool marks could be detected. The scanning process did require some work to minimize the intrusion of the large part gripper. For very small objects it is advisable to construct a custom rig for scanning that can then be attached to the part gripper.

|  |

Fig. 3 - Scans of the clay pipe (left) and a nail (right) from Montpelier.

Once scanning is complete and the scans have been combined and optimized, the NextEngine ScanStudio software transfers the data seamlessly to SolidWorks, an industrial-design digital-modeling program. The 3D-modeling software Rhino 3D also imports the ScanStudio data for analysis and manipulation. The model can then be exported via the secondary modeling software to different model formats. ScanStudio exports directly in STL, OBJ, VRML, UD3 and PLY formats

Serious efforts to benchmark the scanner performance and determine the best place in the spectrum of scanning options for the NextEngine product are underway. Professor Gabriele Guidi of the department of Industrial Design (INDACO) at the Polytecnico in Milan, Italy, is currently performing a battery of tests on the accuracy and precision of the Desktop 3D Scanner that will be available as a white paper later this summer. Preliminary results have been very encouraging. This article will be updated with a link to the white paper when it is available on the web.

If the manufacturers of larger, environment- and architectural-feature scanners can assemble similar technology packages that address ease of use, technology integration, software design and cost with the same rigor shown by NextEngine with the Desktop 3D Scanner, affordable technology will be available across the range of scanning applications and will be accessible to even the smallest project. The recording of archaeological objects and features with such high fidelity opens archaeology to new areas of computational analysis. The distribution of these complex digital representations to researchers and classrooms will perhaps change archiving and research practices and enrich teaching. Pairing recording technology with 3D printing technologies also provides conservators and archivists an alternative to handling or testing originals.

Performance Specifications:

NextEngine, Inc., 401 Wilshire Blvd., Ninth Floor, Santa Monica, California 90401, Fax 310 883 1860

www.nextengine.com

-- Dean Abernathy

For other Newsletter articles concerning the use of electronic media in the humanities, consult the Subject index.

Next Article: The Arachne Object-database

Table of Contents for the Spring, 2007 issue of the CSA Newsletter (Vol. XX, no. 1)

Table of Contents for all CSA Newsletter issues on the Web

Table of Contents for all CSA Newsletter issues on the Web

| CSA Home Page |